Sisters With Rare Disorder Make Dramatic Leaps With New Therapy After Doctors Said They'd Never Walk or Talk

Even for something as rare as a CASK Disorder, the miracles of modern medicine can lend a healing hand, as they did for Anna Burkhart.

If you've ever tried gift-wrapping an odd-shaped present like a teddy bear, you can appreciate the challenge that surgeons face when grafting artificial skin onto an injured body part.

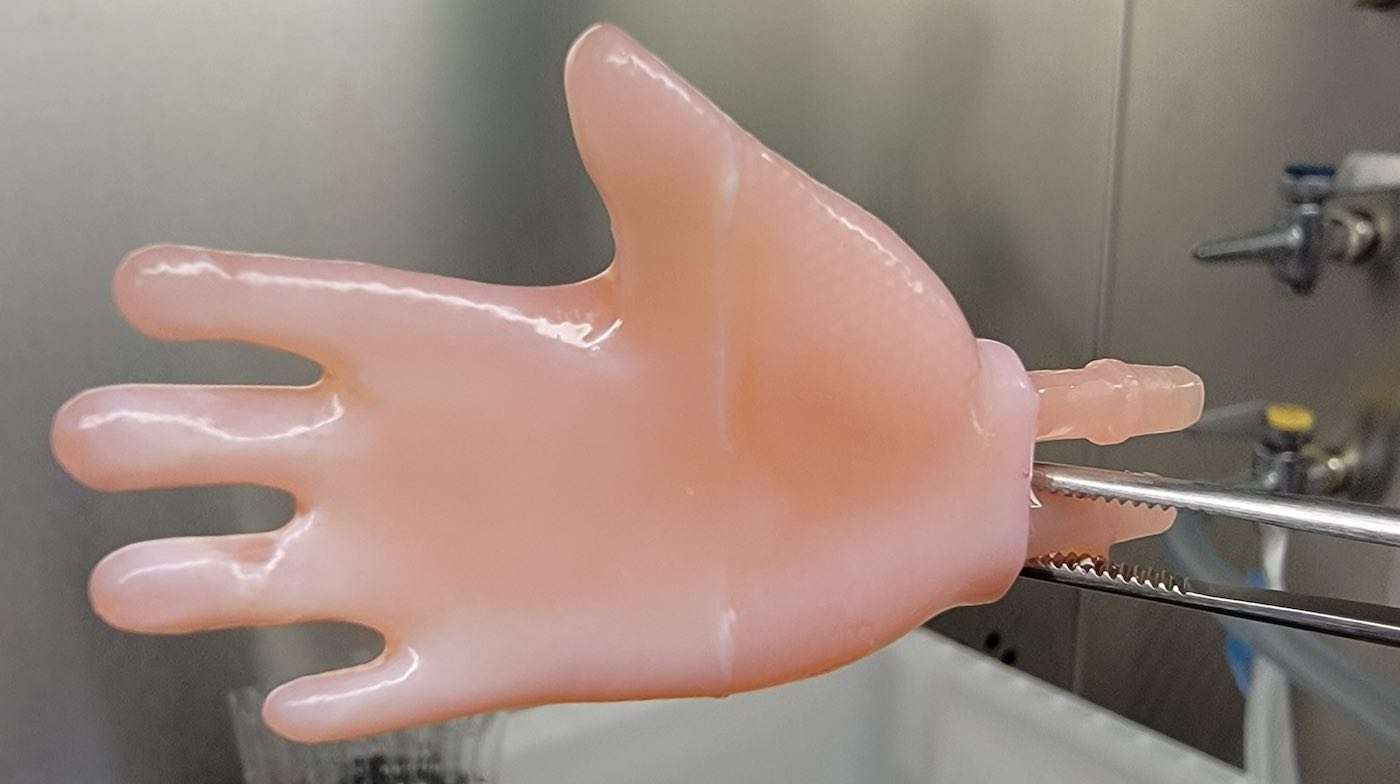

Now, bioengineers have devised a way of growing skin in the shape of hands to make it easier for surgeons in the future to graft the personalized skin onto burn victims.

Currently, engineered skin comes in flat pieces which, like wrapping paper, can be difficult and time-consuming to stitch together around an irregularly shaped body part, such as a hand or foot.

Columbia University researchers say engineering skin cells into complex, three-dimensional shapes in experiments using mice is a groundbreaking first step.

"Three-dimensional skin constructs that can be transplanted as 'biological clothing' would have many advantages," said lead developer Hasan Erbil Abaci, PhD, assistant professor of dermatology at the university's Vagelos College of Physicians and Surgeons. "They would dramatically minimize the need for suturing, reduce the length of surgeries, and improve aesthetic outcomes."

The study, published last week in Science Advances, also revealed that the continuous 3D grafts have better mechanical and functional properties than conventional, pieced-together grafts.

"We hypothesized that a 3D fully-enclosed shape would more closely mimic our natural skin and be stronger mechanically, and that's what we found," Abaci says. "(It) significantly improves the composition, structure, and strength of the graft."

"Another compelling use would be face transplants, where our wearable skin would be integrated with underlying tissues like cartilage, muscle, and bone, offering patients a personalized alternative," Abaci says.

The process of creating the new skin grafts begins with a 3D laser scan of the target structure, such as a human hand. Next, a hollow, permeable model of the hand is crafted using computer-aided design and 3D printing.

The exterior of the model is then seeded with skin fibroblasts, which generate the skin's connective tissue, and collagen (a structural protein). Finally, the outside of the mold is coated with a mixture of keratinocytes (cells that comprise most of the outer skin layer, or epidermis) and the inside is perfused with growth media, which support and nourish the developing graft.

Except for the 3D scaffold, the researchers employed the same procedures used to make flat engineered skin and the entire process took the same time, about three weeks.

In a first test of the 3D engineered skin, constructs composed of human skin cells were successfully grafted onto the hind limbs of mice.

"It was like putting a pair of shorts on the mice," Abaci says, "The entire surgery took about 10 minutes."

Four weeks later, the grafts had completely integrated with the surrounding mouse skin, and the mice reacquired full functions of the limb.

Mouse skin heals differently than human skin, so clinical trials on humans are likely years away.

The researchers say their 3D grafts are the first major re-design of engineered skin grafts since they were first introduced in the early 1980s.

"Engineered skin started with only two cell types, but human skin has around 50 types of cells. Most research had focused on mimicking the cellular components of human skin," Abaci said. "As a bioengineer, it's always bothered me that the skin's geometry was overlooked and grafts have been made with open boundaries, or edges. We know from bioengineering other organs that geometry is an important factor that affects function."

Abaci and his team realized they could make more lifelike grafts when 3D printers became available and could create three-dimensional scaffolds necessary for making the engineered skin.

In the future, Abaci envisions grafts could be custom-made from a patient's own cells. With only a 4X4 mm skin sample, enough cells can be cultured and multiplied to create enough skin to cover a human hand.

SHARE the Advancement With Medical Professionals on Social Media…

Be the first to comment