The Hubble and Webb Telescopes Join to Create Unprecedented Photo of Universe

The bluest galaxies are relatively nearby and detected by Hubble, while the redder galaxies tend to be more distant as detected by Webb.

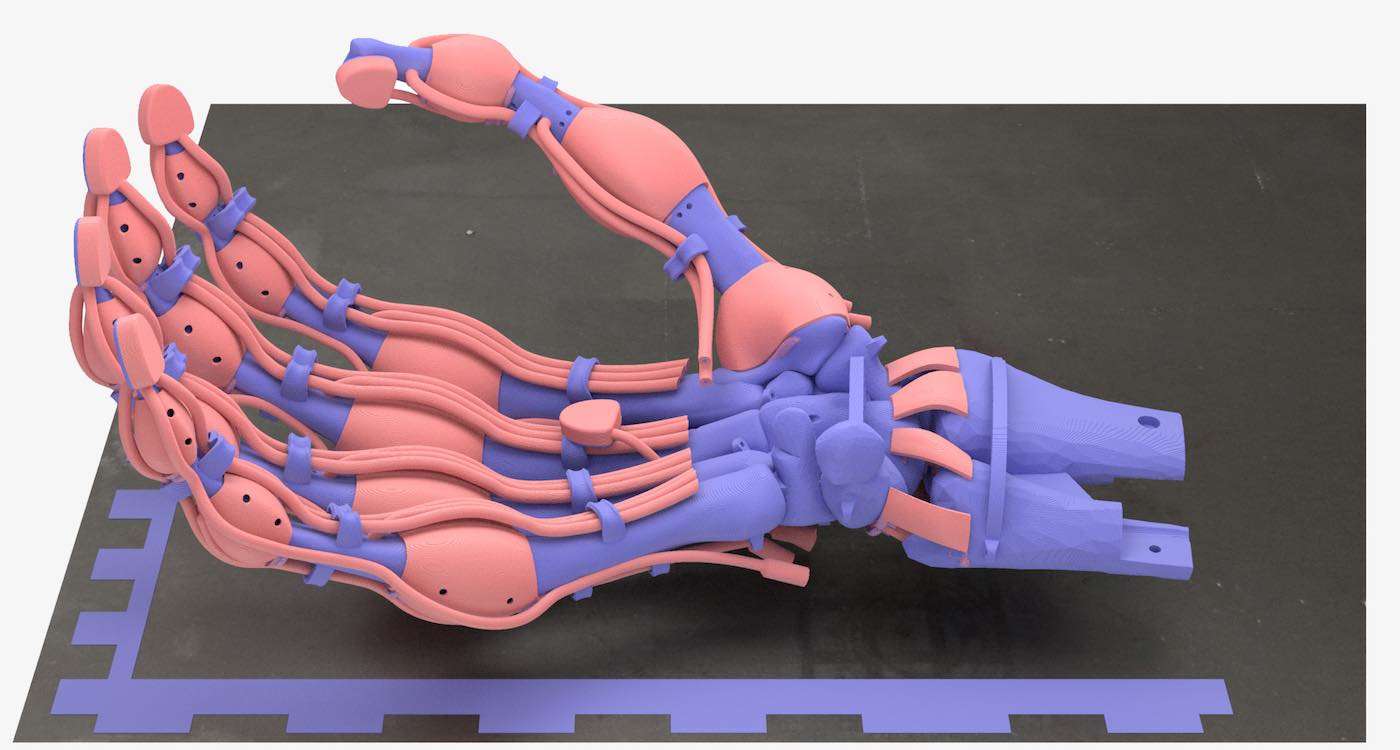

Using new innovations in 3D printing, scientists at ETH Zurich have succeeded for the first time in printing a robotic hand with bones, ligaments, and tendons—all made of different polymers in one go.

The various polymers can be fine-tuned to replicate the elasticity or rigidity of a human hand, representing a major advancement over existing 3D-printed prosthetics.

While 3D printing technology was previously limited to fast-curing plastics, researchers have now made it suitable for slow-curing plastics as well.

They say these materials have "decisive" advantages as they have enhanced elastic properties and are more durable and robust.

The use of such polymers is made possible by new technology developed by researchers at ETH Zurich in Switzerland and a US startup from Mass. Institute of Technology which can be used to create delicate structures and parts with cavities as desired. InkBit from MIT now offers the technology and prints complex objects on customer request.

The technology also makes it easy to combine soft, elastic, and rigid materials.

"We wouldn't have been able to make this hand with the fast-curing polyacrylates we've been using in 3D printing so far," said Thomas Buchner, a doctoral student from ETH Zurich who led the authorship of the paper published on their work.

"We're now using slow-curing thiolene polymers. These have very good elastic properties and return to their original state much faster after bending than polyacrylates," he said, adding this makes them ideal for making complex prosthetics.

"Robots made of soft materials, such as the hand we developed, have advantages over conventional robots made of metal," said ETH Zurich robotics professor Robert Katzschmann. "Because they're soft, there is less risk of injury when they work with humans, and they are better suited to handling fragile goods."

Usually, 3D printers produce objects layer by layer: nozzles deposit a given material in viscous form at each point; a UV lamp then cures each layer immediately.

To accommodate the use of slow-curing polymers, the researchers added a 3D laser scanner that immediately checks each printed layer for any surface irregularities.

A feedback mechanism compensates for these irregularities when printing the next layer by calculating any necessary adjustments to the amount of material to be printed in real-time and with pinpoint accuracy.

The researchers from Switzerland and the US jointly published the technology and their sample applications in the journal Nature.

WATCH the details of their innovations in this cool video…

SHARE This Futuristic Advancement From MIT And Zurich With Your Friends…

Be the first to comment