New Solar-Powered Invention Creates Hydrogen Fuel from the Air

This sponge uses electrolysis to extract hydrogen, and can be powered by green energy, producing renewable fuel from renewable electricity.

We could 3D-print tools on Mars made from the planet itself—and the exciting experiment could change the future of space travel, according to engineers.

The breakthrough means that future missions will be able to print essentials for repairs such as spare parts for rockets.

It's a significant discovery because researchers say they can't carry everything out to space, and if they forget a tool on a mission they can't come back to get it.

Taking materials out there is also hugely expensive, noted the study's authors: it costs $54,000 to put just one kilogram (2.2 lb) of material into the Earth's orbit.

As a result, researchers at Washington State University in the US believe 3D-printing is the burgeoning field that could be the answer to make space travel cheaper and easier.

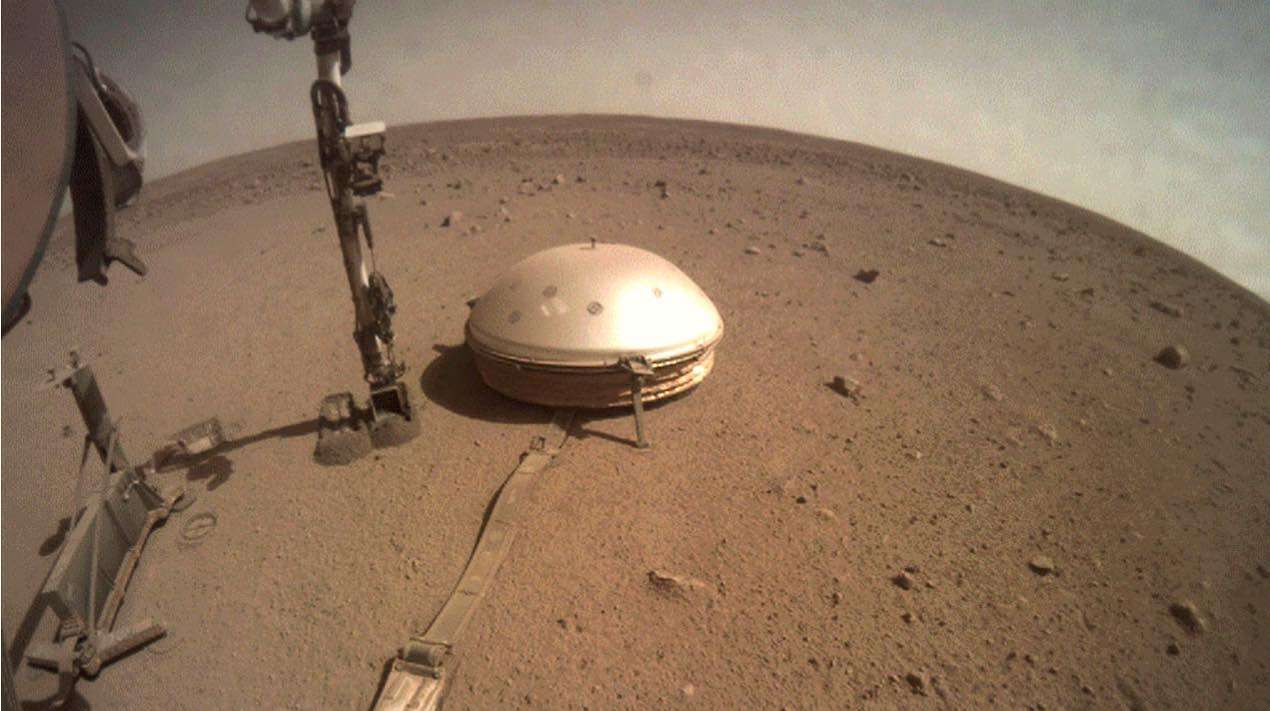

The team discovered small amounts of simulated crushed Martian rock, mixed with titanium alloy, made a strong, high-performance material that could be used to make tools and rocket parts on the red planet.

They made tools using between 5% and 100% Martian regolith, a black powdery substance intended to imitate the rocky, inorganic material on Mars' surface that could be collected by a robotic arm or rover.

When it came to adding just 5% of Martian dust in the mix, there were no cracks or bubbles and it was far better than just titanium alloys.

They believe this combination could be used to build lighter weight pieces still capable of carrying heavy loads.

"It gives you a better, higher strength and hardness material, so that can perform significantly better in some applications," said the study's corresponding author Professor Amit Bandyopadhyay.

Meanwhile the 100 percent concentration parts were brittle and cracked easily. However Prof. Bandyopadhyay reckons 100% Martian rock materials would still be great as coatings to defend against rust or radiation damage.

Alongside graduate students Ali Afrouzian and Kellen Traxel, Bandyopadhyay used a powder-based 3D printer to mix up the fake Martian rock with titanium alloy, a metal commonly used in space because it is light, strong, and heat-resistant.

A high-powered laser shot through the materials to get them up to 2,000 degrees Celsius. After that, the melted mixture flowed into a moving platform where researchers could create it into varying sizes and shapes.

Once it cooled, they tested it for durability and strength to reveal the exciting new options in space travel.

But more is possible and, publishing their research in the International Journal of Applied Ceramic Technology, the team reckons there are even better composites to be found using different metals and printing techniques.

"This establishes that it is possible, and maybe we should think in this direction because it's not just making plastic parts which are weak but metal-ceramic composite parts which are strong and can be used for any kind of structural parts," added Bandyopadhyay, who worked on similar experiments using simulated crushed moon rock (lunar regolith) for NASA in 2011.

Since then space agencies have worked more and more with 3D printing, and the International Space Station now has its own devices to manufacture the materials they need on site and for experiments.

Manufacture Some Mars-velous Curiosity on Social Media By Sharing…

Be the first to comment